Wood is one of nature’s most versatile resources, prized for its beauty, durability, and functionality. While all woods have their unique characteristics, some are significantly harder and more durable than others. If you’ve ever wondered, “Which country has the hardest wood?” then you’re in the right place.

Understanding wood hardness is crucial for anyone working in construction, furniture making, or even musical instrument crafting, as it can affect the longevity and resilience of the finished product.

Wood hardness is a measure of a wood species’ resistance to wear, denting, and scratching. It’s an essential factor in determining how well the wood will hold up in various applications, from high-traffic flooring to durable furniture and industrial uses. Harder woods are typically more resistant to physical damage, making them a preferred choice for areas that demand strength and endurance.

The Janka Hardness Test

Wood hardness is typically measured by the Janka hardness test. This test assesses the force required to embed a steel ball with a diameter of 0.444 inches halfway into a sample of wood. The higher the force needed, the harder the wood. The Janka rating is expressed in pounds-force (lbf) or newtons (N), and it provides a standardized measure to compare different woods’ hardness levels.

How Does the Janka Test Work?

During the test, a steel ball is pressed into the wood sample at a controlled rate until half of the ball is embedded in the surface. The force required to achieve this is recorded as the Janka hardness rating. For instance, a wood with a Janka rating of 5,000 lbf is significantly harder than one with a rating of 1,000 lbf, making it more resistant to wear and tear.

Importance of Wood Hardness in Various Industries

Wood hardness plays a significant role in determining its application. Here are some areas where hardness is critical:

- Flooring: Harder woods are ideal for high-traffic flooring as they resist dents and scratches.

- Furniture: For long-lasting furniture, hard woods provide durability and elegance.

- Construction: Heavy-duty construction projects require wood that can withstand pressure and stress.

- Musical Instruments: Specific hardness levels affect sound quality in instruments like guitars and pianos.

Understanding wood hardness is essential for making informed decisions in each of these industries. Hardness often dictates how a wood will perform over time and the type of maintenance it will need.

Why is Wood Hardness Important?

The hardness of wood is more than just a technical measure; it’s a key factor in determining a wood’s durability and suitability for specific uses. Harder woods are known for their longevity and are less likely to sustain damage from regular use. Here are some reasons why wood hardness matters:

Durability and Longevity

Harder woods generally last longer than softer ones. They are more resilient to wear and can withstand years of use without showing significant signs of damage. For instance, Brazilian cherry and hickory, both known for their high hardness, can maintain their appearance and strength in high-traffic areas for decades.

Resistance to Damage

Wood hardness directly correlates with resistance to scratches, dents, and other forms of damage. This is why harder woods are often used for floors, countertops, and tabletops that face daily wear.

Ease of Maintenance

While harder woods are more resistant to damage, they may require more specialized tools and effort when cutting or working with them. Additionally, hard woods like Australian Buloke and Lignum Vitae are challenging to saw and shape, often necessitating industrial-strength tools.

Common Misconceptions About Wood Hardness

There are several misconceptions surrounding wood hardness. Below are some of the most common ones:

1. Hardness Equals Density

One misconception is that wood hardness is the same as wood density. While they are related, they are not identical. Hardness measures resistance to indentation, whereas density measures the mass per unit volume. Some woods are dense but not particularly hard, while others are extremely hard but not very dense.

2. Harder Woods are Always Better

Harder woods aren’t always the best choice. Depending on the project, softer woods may be more suitable. For instance, softer woods like pine are easier to shape and are ideal for decorative pieces, while harder woods may be too difficult to work with for fine details.

3. Wood Hardness is Only Important for Floors

While floors benefit greatly from hard woods, so do other products like furniture, tool handles, and sporting equipment. Hardness enhances the durability of any wooden item, ensuring it withstands frequent use and heavy pressure.

4. All Hardwoods are Hard

Interestingly, not all hardwoods are hard, and not all softwoods are soft. Hardwood and softwood refer to the tree species rather than the wood’s actual hardness. For example, balsa wood is technically a hardwood, but it is one of the softest woods available.

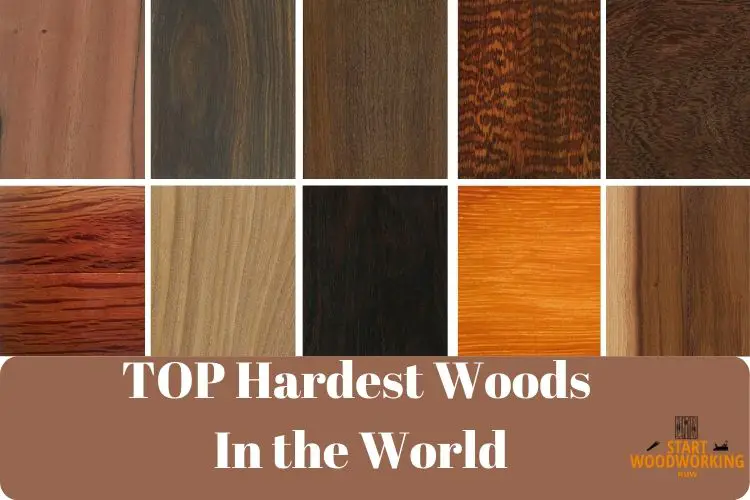

Which Types of Wood Are the Hardest in the World?

When it comes to the hardest woods in the world, a few species consistently rank at the top due to their incredibly high Janka hardness ratings. These woods come from diverse regions, each adapted to unique climates and growing conditions that contribute to their strength. Below are some of the world’s hardest woods, along with their Janka hardness ratings and origins.

1. Australian Buloke (5,060 lbf)

- Origin: Australia

- Characteristics: Known as one of the hardest woods on the planet, Australian Buloke is native to eastern and southern Australia. Its hardness and density make it highly resistant to scratches and dents, making it ideal for flooring and heavy-duty construction.

- Applications: Due to its extreme hardness, Australian Buloke is used primarily in industrial settings. However, it’s also popular in fine woodworking and cabinetry for its durability and attractive grain.

2. Lignum Vitae (4,500 lbf)

- Origin: Caribbean and South America

- Characteristics: Often referred to as “wood of life,” Lignum Vitae is one of the densest and hardest woods in the world. It has natural oils that make it self-lubricating, which is unique among woods.

- Applications: Historically used in shipbuilding and bearings for machinery, Lignum Vitae is highly valued for its hardness and ability to withstand intense pressure and friction.

3. Quebracho (4,570 lbf)

- Origin: South America (Argentina, Paraguay, and Bolivia)

- Characteristics: Named for its ability to “break an ax,” Quebracho is renowned for its density and strength. It is primarily used in South America, where its durability is especially prized in construction and fencing.

- Applications: Due to its hardness, Quebracho is used in construction, as railroad ties, and for firewood. It’s also used in traditional medicine and tanning due to its high tannin content.

4. Snakewood (3,800 lbf)

- Origin: Central and South America

- Characteristics: Known for its unique, snake-like grain pattern, Snakewood is one of the densest and hardest woods. Its beauty and hardness make it a highly sought-after wood for luxury items.

- Applications: Primarily used for specialty items like violin bows, knife handles, and high-end furniture. Snakewood is popular among artisans for its striking appearance and durability.

5. Black Ironwood (3,660 lbf)

- Origin: United States and the Caribbean

- Characteristics: Black Ironwood is one of the hardest woods found in North America. Its dark color and hardness make it a popular choice for decorative and functional woodworking projects.

- Applications: Often used in tool handles, knife scales, and specialty items. Its hardness and density also make it resistant to decay, making it suitable for outdoor applications.

Hardest Woods and Their Janka Ratings

| Wood Type | Janka Hardness (lbf) | Primary Origin | Main Uses |

|---|---|---|---|

| Australian Buloke | 5,060 | Australia | Flooring, cabinetry, industrial tools |

| Lignum Vitae | 4,500 | Caribbean, South America | Bearings, shipbuilding, industrial use |

| Quebracho | 4,570 | South America | Construction, railroad ties, fencing |

| Snakewood | 3,800 | Central, South America | Violin bows, luxury items |

| Black Ironwood | 3,660 | USA, Caribbean | Tool handles, knife scales, outdoor use |

Wood Hardness Ratings – How Do They Compare?

In the table above, you’ll notice the impressive Janka hardness ratings of each wood. While all of these woods are extremely hard, Australian Buloke tops the list with a Janka rating of 5,060 lbf, making it the hardest wood tested to date. This high rating indicates that Buloke requires more force to dent or scratch, making it ideal for heavy-duty applications.

However, each wood in the list has unique properties beyond hardness alone. For example, Lignum Vitae’s self-lubricating properties make it especially valuable in applications where friction is a concern, such as machinery parts. Similarly, the striking grain of Snakewood adds an aesthetic appeal that makes it popular for high-end decorative items.

Practical Implications of Wood Hardness Ratings

Understanding these ratings helps consumers and professionals choose the right wood for their needs:

- Industrial Applications: Woods like Australian Buloke and Lignum Vitae are suitable for demanding applications due to their exceptional hardness.

- Decorative Uses: Snakewood and Black Ironwood, though hard, are often chosen for their unique appearances, adding aesthetic value to finished pieces.

- Durability and Maintenance: Harder woods may require less frequent replacement or repair, especially in high-wear environments like floors.

By examining these woods’ Janka hardness ratings and applications, we can appreciate how each species’ properties contribute to its popularity and use.

Which Country Has the Hardest Wood?

After exploring the hardest woods globally, we arrive at the central question: Which country has the hardest wood? The answer, based on the Janka hardness test, points to Australia as the home of the hardest wood species: Australian Buloke. This wood, with a Janka hardness rating of 5,060 lbf, holds the top position for its unparalleled density and resilience.

Where Does the Hardest Wood in the World Grow?

Australian Buloke, a native species, grows in Eastern and Southern Australia, particularly in areas with arid climates. This hardwood belongs to the casuarina tree family, known for its tough, fibrous structure and incredible density. Australian forests, shaped by a unique set of environmental factors, produce some of the hardest and most resilient wood on the planet.

However, Australia isn’t the only country that produces extremely hard woods. Several countries in South America and the Caribbean also grow species with high Janka ratings, such as Quebracho in Argentina and Lignum Vitae in Jamaica. Still, these species fall just short of Australian Buloke’s record-breaking hardness.

Why Does Australia Produce Some of the Hardest Wood?

Australia’s extreme climate and unique ecological conditions contribute significantly to the hardness of its wood species. Here are some factors that help explain why Australia produces such tough woods:

- Climate Extremes: Australia experiences intense heat, prolonged dry seasons, and even wildfires. Trees that thrive in these harsh conditions are slow-growing and develop dense, durable wood. Australian Buloke, for instance, has adapted to withstand fire and extreme weather, resulting in a very hard wood.

- Slow Growth: Trees in arid climates tend to grow slower, which contributes to the density of their wood. Slow growth means more tightly packed wood fibers, making the wood harder and more resilient to wear.

- Evolutionary Adaptations: Australian woodlands and forests have evolved over millions of years under challenging conditions. Species like the casuarina family (which includes Australian Buloke) have adapted to resist pests, disease, and environmental stresses, all of which contribute to the wood’s incredible hardness.

Australia’s hardwoods, therefore, are not only hard due to their growth structure but are also highly resistant to environmental factors that might damage or weaken other types of wood.

Other Countries Known for Hard Woods

Though Australia claims the title of the hardest wood with Australian Buloke, other countries also produce remarkably hard woods that are prized worldwide:

- Brazil and Argentina: These countries are home to Quebracho, which ranks among the world’s hardest woods with a Janka rating of around 4,570 lbf. Quebracho’s name translates to “ax-breaker” in Spanish, reflecting its extreme toughness and density.

- Jamaica and South America: Lignum Vitae, found in the Caribbean and parts of South America, holds a Janka rating of 4,500 lbf. Its dense, oily structure makes it resistant to friction, making it invaluable in machinery and marine applications.

- The United States: While most North American woods are softer than those found in Australia and South America, Black Ironwood is a notable exception, reaching a Janka hardness of 3,660 lbf. This wood is prized for tool handles, furniture, and outdoor uses.

Comparing Wood Hardness Across Countries

When comparing wood hardness globally, Australia’s Buloke consistently ranks at the top due to its unparalleled hardness. South American and Caribbean countries follow closely, with species like Quebracho and Lignum Vitae that offer impressive durability and strength. This comparison highlights how various environmental conditions influence wood hardness, with each country’s trees adapted to their unique ecosystems.

| Country | Hardest Wood Species | Janka Hardness (lbf) |

|---|---|---|

| Australia | Australian Buloke | 5,060 |

| Argentina | Quebracho | 4,570 |

| Jamaica | Lignum Vitae | 4,500 |

| United States | Black Ironwood | 3,660 |

Australia, due to its distinctive climate and ecological factors, remains the top contender in terms of wood hardness. Its hardwood species, especially Australian Buloke, have adapted to survive in harsh conditions, resulting in wood that outperforms other types in durability and strength.

Uses of the Hardest Woods

The incredible hardness of woods like Australian Buloke, Lignum Vitae, and Quebracho makes them ideal for specific applications where durability and resistance to wear are paramount. These woods are not only strong but also capable of withstanding extreme conditions, making them valuable in both industrial and high-end craftsmanship contexts. Below, we’ll explore some of the primary uses of the world’s hardest woods and why their unique properties are sought after in various industries.

What Are the Hardest Woods Used For?

The hardest woods are commonly used in applications where durability is essential. Their density and resistance to dents and scratches make them ideal for environments that experience frequent use or heavy pressure. Here are some of the main uses for these woods:

- Industrial Applications

- Heavy-duty Flooring: Hardwoods like Australian Buloke and Quebracho are often used in heavy-duty flooring for industrial spaces, gyms, or high-traffic commercial areas. Their density helps prevent damage from heavy equipment or constant foot traffic.

- Machinery Bearings: Lignum Vitae, in particular, is unique for its self-lubricating properties, making it a valuable material for bearings and other machinery parts. It has historically been used in shipbuilding, especially for propeller shafts and bearings, due to its ability to withstand friction and pressure.

- Construction and Outdoor Applications

- Railroad Ties and Fencing: Quebracho wood from South America is known for its strength and decay resistance, making it a preferred choice for railroad ties and outdoor fencing. Its hardness allows it to withstand environmental factors that might cause other woods to degrade over time.

- Tool Handles and Agricultural Implements: Hardwoods like Black Ironwood are used to make tool handles, especially for heavy tools like axes and hammers. The hardness and strength of these woods help prevent breakage, even under intense strain.

- Furniture and Cabinetry

- High-End Furniture: Snakewood and Black Ironwood are often used in luxury furniture due to their beautiful grain patterns and durability. Snakewood, with its unique snake-like markings, is especially prized for decorative items.

- Cabinetry: Due to its hardness and density, Australian Buloke is sometimes used in cabinetry for high-end homes and commercial spaces. Its strength and resistance to wear make it a desirable option for cabinets that need to withstand daily use.

- Specialty Uses and Crafts

- Musical Instruments: Some of the hardest woods are used in musical instruments for their resonance and durability. For example, certain hardwoods are used for violin bows, guitar fingerboards, and percussion instruments due to their ability to produce a clear sound and withstand constant use.

- Luxury Items and Accessories: Snakewood and Lignum Vitae are used to create small luxury items like knife handles, watch cases, and decorative pieces. Their density, unique textures, and natural luster make them ideal for high-end crafts.

Benefits and Challenges of Using the Hardest Woods

Using the hardest woods offers significant benefits, but it also comes with challenges:

- Benefits: These woods offer exceptional durability, resistance to wear, and often unique aesthetic qualities. For applications that require long-lasting materials—like industrial machinery, outdoor constructions, and luxury goods—the hardest woods are a superior choice.

- Challenges: The density of these woods can make them difficult to work with. Hardwoods like Australian Buloke require specialized tools to cut, shape, and finish. Additionally, due to their slow growth rate and rarity, many of these woods are expensive and may have limited availability.

Examples of Hard Wood Applications in Real Life

- The USS Constitution: The USS Constitution, a U.S. Navy warship, famously used Lignum Vitae in its construction. This wood’s natural oils and resistance to saltwater helped the ship withstand long periods at sea.

- Historic Railroads in South America: Quebracho wood has been used in railroad ties for historic railroads throughout South America, where its toughness has allowed it to survive in challenging weather conditions over decades.

- Luxury Violin Bows: Snakewood is often used in high-end violin bows due to its density and unique grain. Its natural strength allows the bow to retain its shape and provide precise control over sound production.

The diverse applications of the hardest woods showcase their value in various fields, from industrial use to luxury craftsmanship. Their extreme hardness offers benefits that softer woods simply cannot match, making them a premium choice for projects requiring strength and durability.